Cold Rolled Coils

Our cold rolled coils are finished with precision to match international standards. They have good shape, high tolerance, versatility and blemish-free surfaces. They are used in commercial and general engineering applications such as bus bodies, cladding and fan blades. The cold rolled coils are manufactured from the hot rolled coils. The hot rolled coils are cleaned chemically and processed further in cold reduction mills, where the material is cooled (at room temperature) followed by annealing and/or tempers rolling.

This process produces steel with closer dimensional tolerances and a wider range of surface finishes. Cold rolling increases strength, enhances the surface finish and offers uniform thickness. To prevent the cold rolled coils from rust, they are usually coated with a thin layer of oil. Further coating of Zinc-Aluminium alloy or galvanization on the metal can be processed. Dmsons offer cold rolled coils in a range of international standard grades.

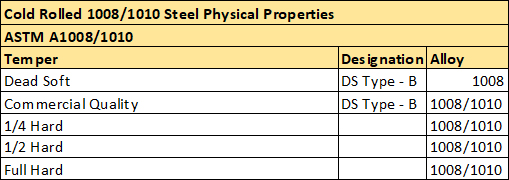

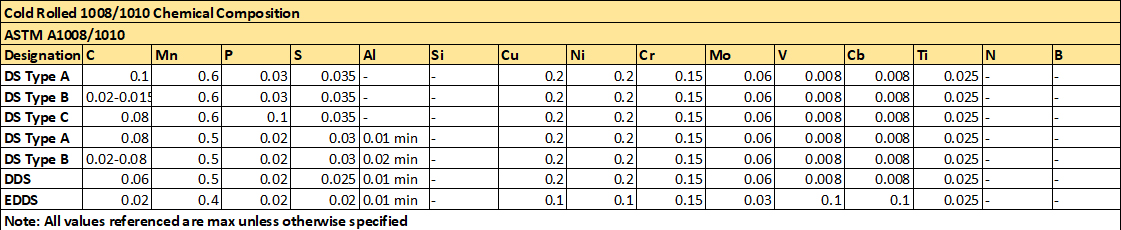

Grades

- A 1008: DS type A & B, DDS, EDDS, EDDS+

Specifications

Mechanical Properties

- Thickness - 0.5mm to 3.15mm

- Width - 800mm to 1600mm

- Material - Mild Carbon Steel

- Length - Can be cut to sheets according to requirement

- Max. Weight - 20 MT per coil

Applications

- Tube making

- Containers and drums

- Shelving

- Automotive parts

- Precision tubes

- Packaging industry