Alloy Steel

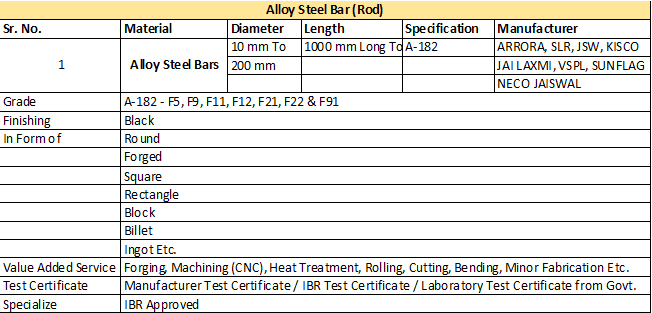

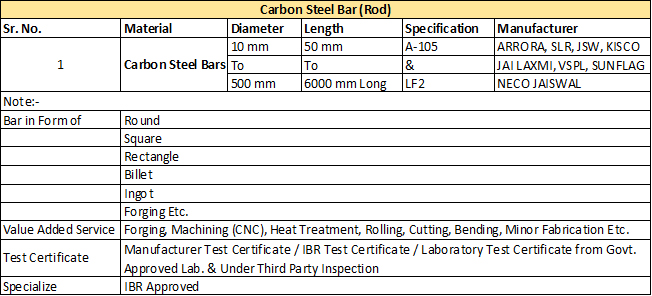

Discover top-grade Alloy Steel Dealers and Suppliers in Uttar Pradesh. Connect with reputable dealers & suppliers for high-quality, durable Alloy Steel solutions. A wide range of Special & Alloy Steels is being manufactured as per BS/EN, IS, JIS, DIN, SAE/AISI/ASTM, GOST standard as per the Customer’s Specifications. The major categories of Special & Alloy Steels we supplied are:

- Plain Carbon Steel (Carbon Manganese Steel Carbon)

- High Manganese Steel

- Chrome Steel

- Chrome Manganese Steel

- Chrome-Moly Steel

- Chrome-Nickel-Moly Steel

- Chrome-Nickel Steel

- Ball Bearing Steel

- Spring Steel

- Sulphur Based Free Cutting Steel

- Boron Steel

- Micro Alloys

- Other Customized grade may be made

- As per customer’s requirement

Grades

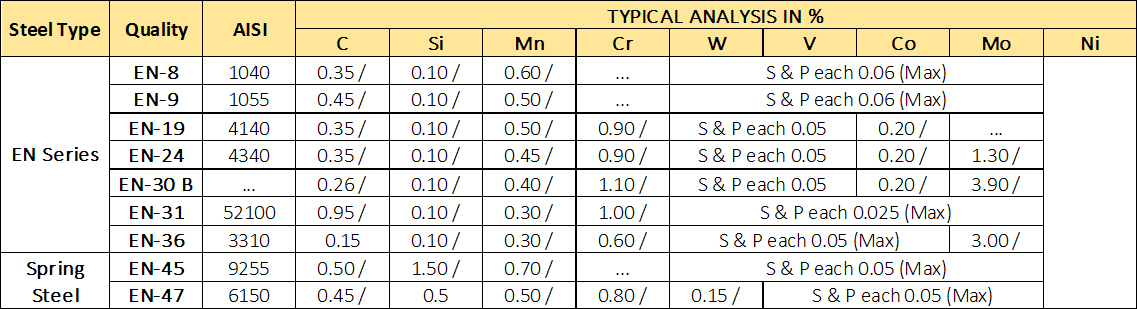

- Alloy Steel , All EN Series(EN8, 9,16,18, 19, 24, 31, 36, 353, 42, 47)

- SAE8620, SAE9260, 20MncrB5, 27MnCrB5, 30MnCrB5

- OHNS , Die Steel(HCHCR, Hot die Steel, High Speed Steel ) forged Round Flats & Square . Spl. in C45 plates MS Plates, Stainless Steel, Brass & Copper

Supply Condition

- Hot Rolled / As Rolled

- Hot Rolled and Annealed

- Hot Rolled and Spherodised Annealed

- Hot Rolled Peeled

- Hot Rolled Peeled and Ground

- Hot Rolled Spherodised Annealed Peeled / Peeled & Ground

- EN-8. Crank shafts, automobile axle beams, connecting rods, Lightly stressed gears.

Generally used for moderately stressed parts of Motor Vehicles and general engineering works. - EN-9. Crank shafts, Cylinders, Gears, Sprockets.

Mainly used in machine parts which require moderate wear resistance. - EN-19. Axle shafts, Crank shafts, Gears, Connecting rods, Studs, Bolts, Propeller shaft joint.

Suitable for heat treated parts where high tensile and impact are required along with high endurance bending strength. - EN-24. Aircraft and heavy vehicle crank shafts, Connecting rods, Gear shafts, Chain parts, Clutches, Propeller shafts, Cam shafts, Spindles, Screws, Studs, Pinions, Tappets, Boring bars.

Preferred to be applied for heat treated components having large sections and subject to exacting requirements. - EN-30. B Application similar to EN-24 Steel.

More Suitable for extra ordinary high toughness purposes. - EN-31. Ball and Roller Bearings, Spinning tools, Beading Rolls, Punches and Dies.

By its character this type of steel has high resisting nature against wear and can be used for components which are subjected to severe abrasion, wear or high surface loading. - EN-36. Disc wheels, Grooved shafts, Cams, Gears, Heavy duty gears for air craft, Heavy vehicle and automobile transmission parts, General engineering works, Universal joints.

Mainly used for highly stressed machine parts which are intended for cementation with high strength and core toughness. - SPRING STEEL

- EN-45. Leaf and volute springs, Road and railway vehicle springs including helical and plate springs.

This steel is capable of taking up a good hardness and possesses an increased stability in temperig. - EN-47. High duty volute and leaf springs, Heavy engine valve springs, Helical and torsional bar springs.

It has a high ratio of yield point to tensile strength and high torsional fatigue strength.